Manufacturing

Built with Precision. Backed by Experience.

Where German Engineering Powers Performance.

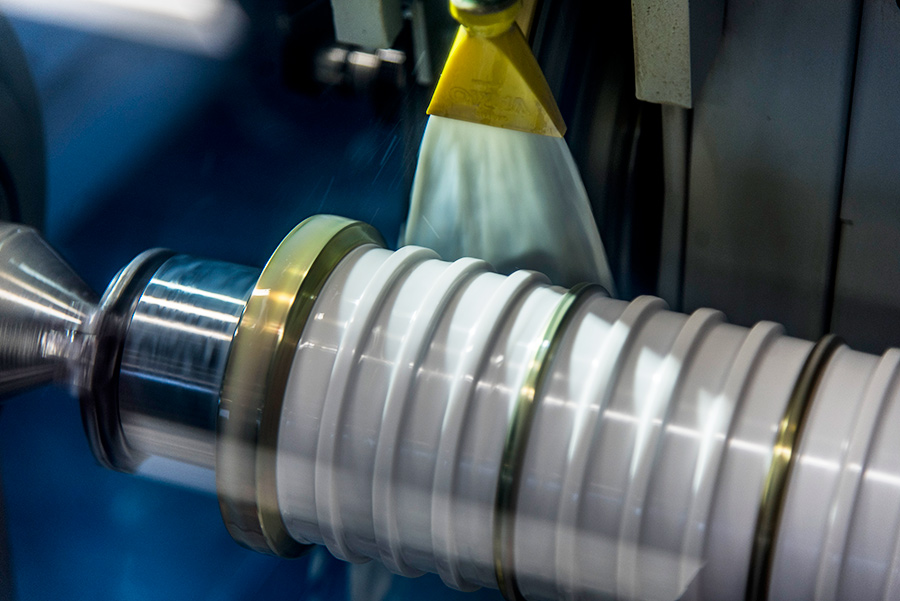

At VT-KÄMPFER, manufacturing is more than production—it’s precision in action. Every tool we make reflects 40+ years of expertise, engineered for accuracy, repeatability, and lasting performance in the toughest wire and cable environments.

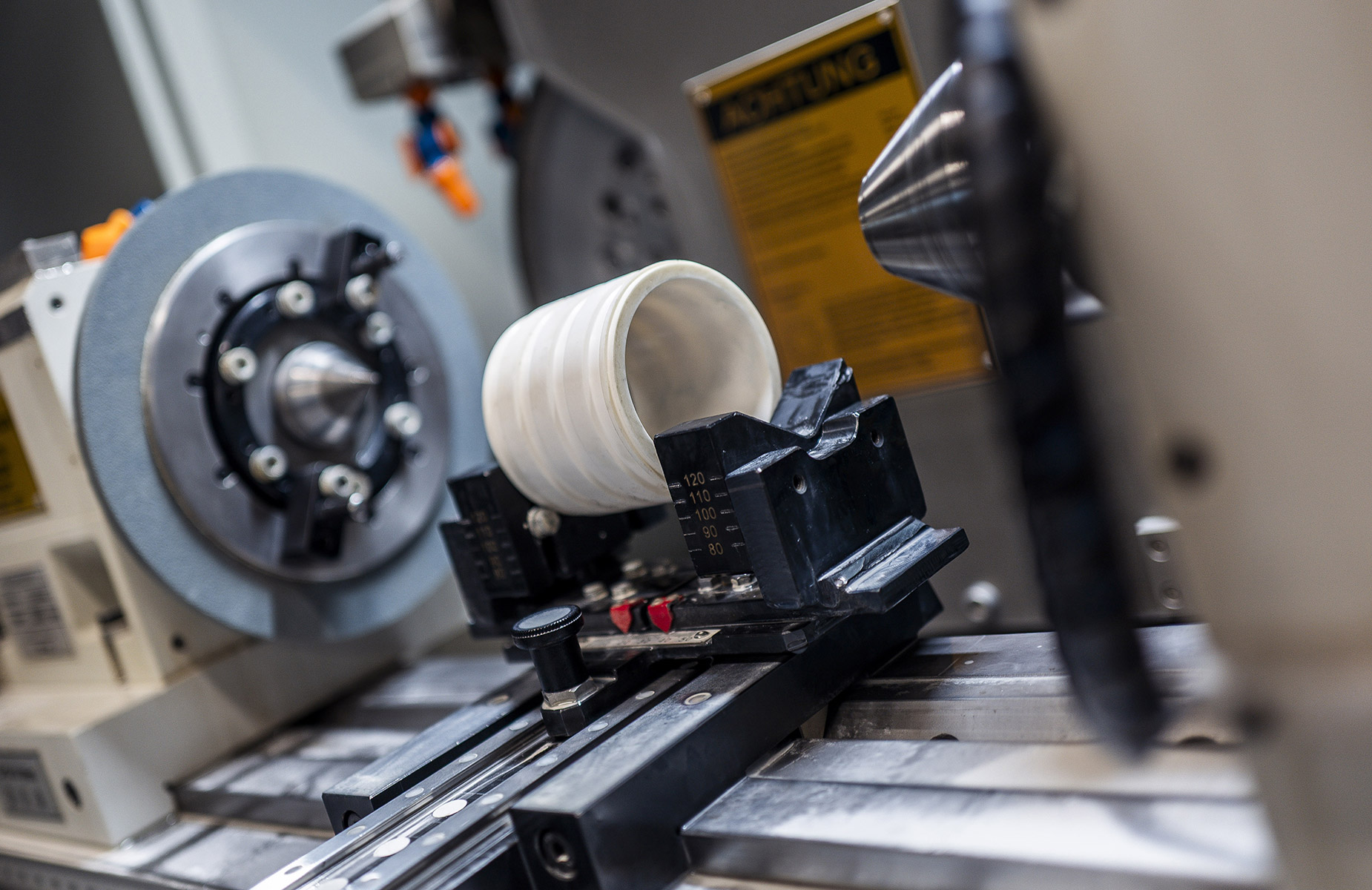

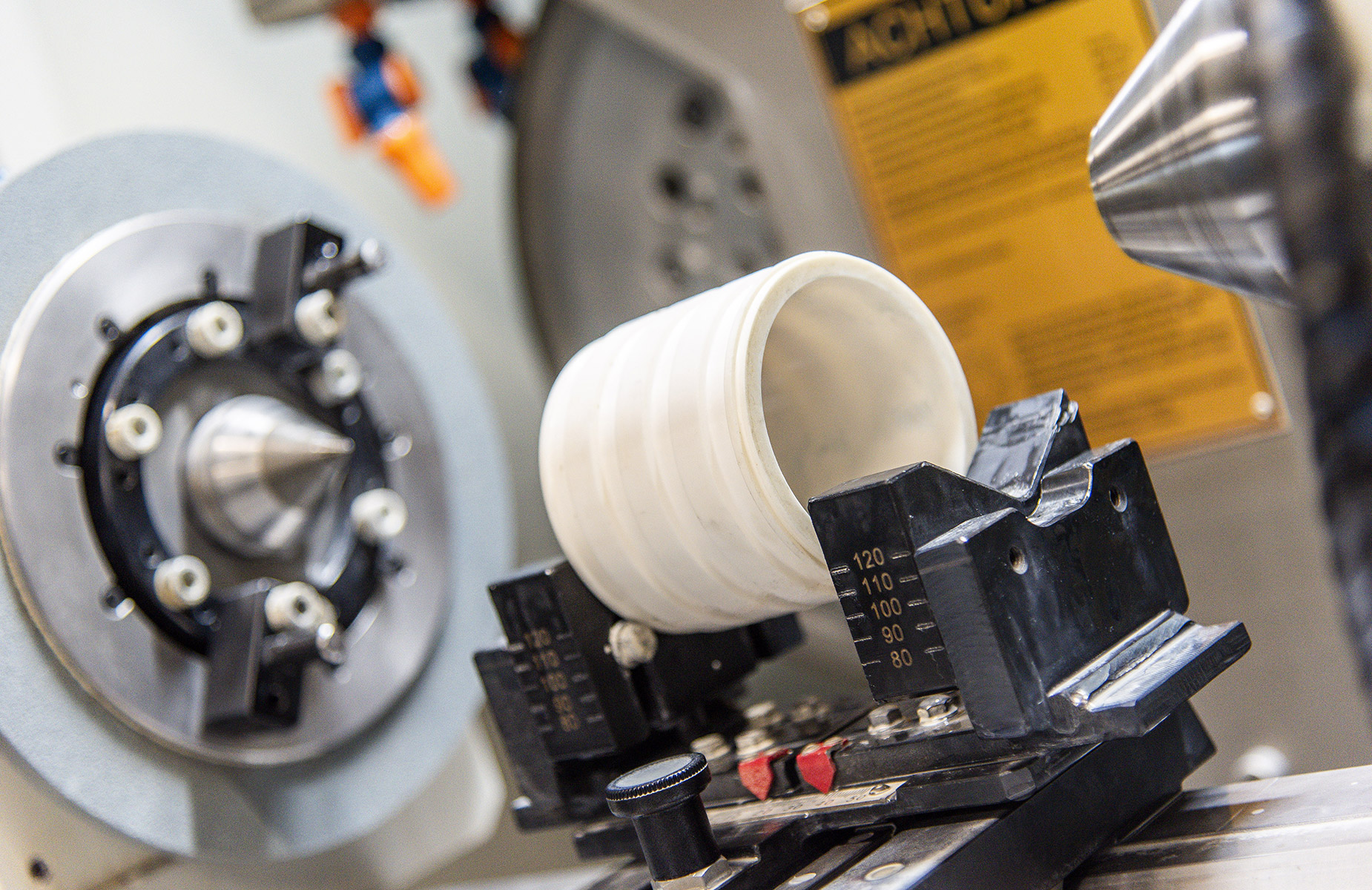

Our In-House Manufacturing Capabilities

Your Line. Our Expertise. One Optimized Solution.

From Herborn, Germany, we bring together precision craftsmanship and advanced manufacturing to deliver tooling solutions with micron-level accuracy and repeatable quality. Every part is built under one roof—ensuring full control, consistent standards, and rapid turnaround.

Core Capabilities

-

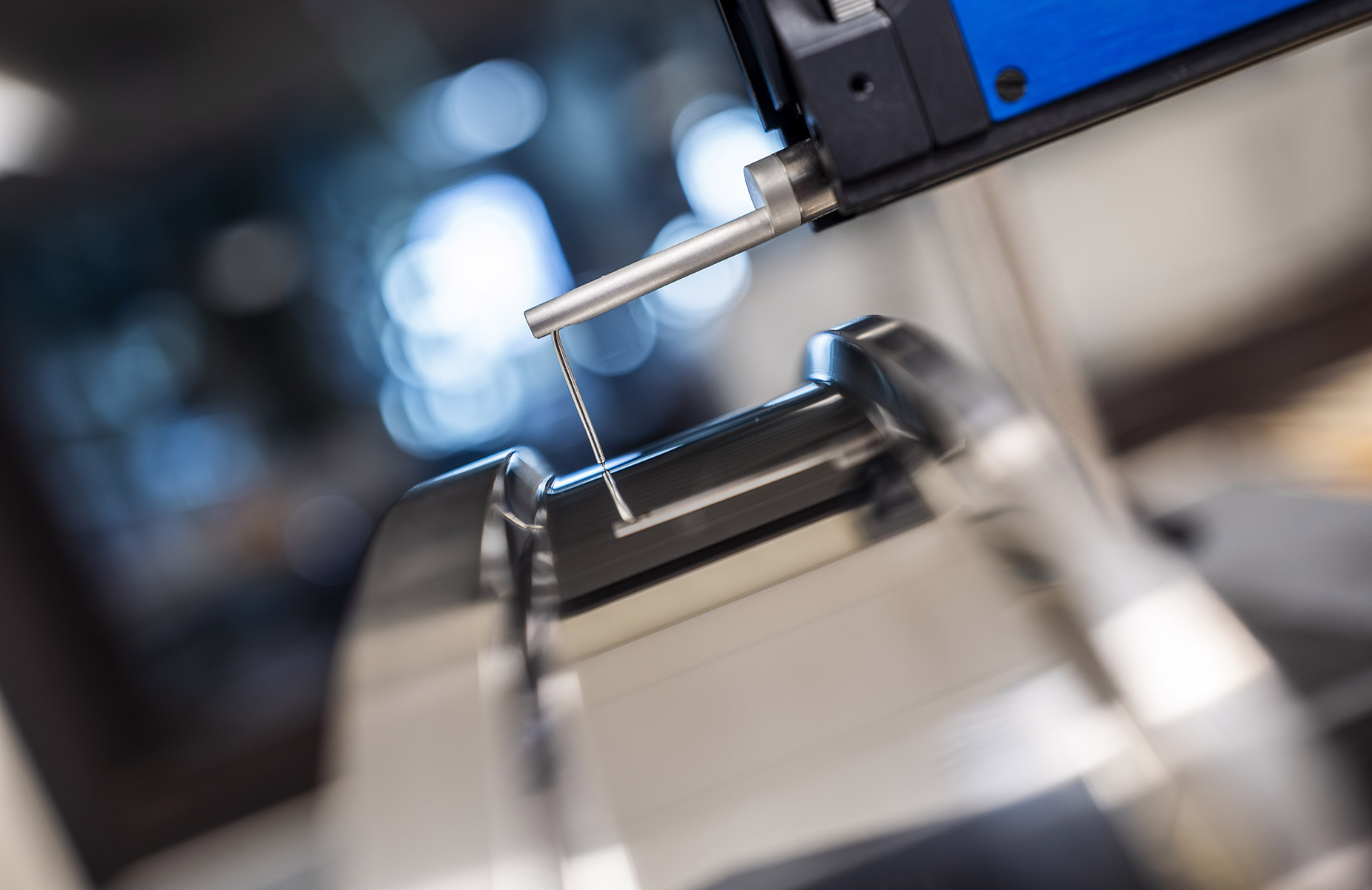

CNC Machining: Multi-axis turning and milling for complex geometries

-

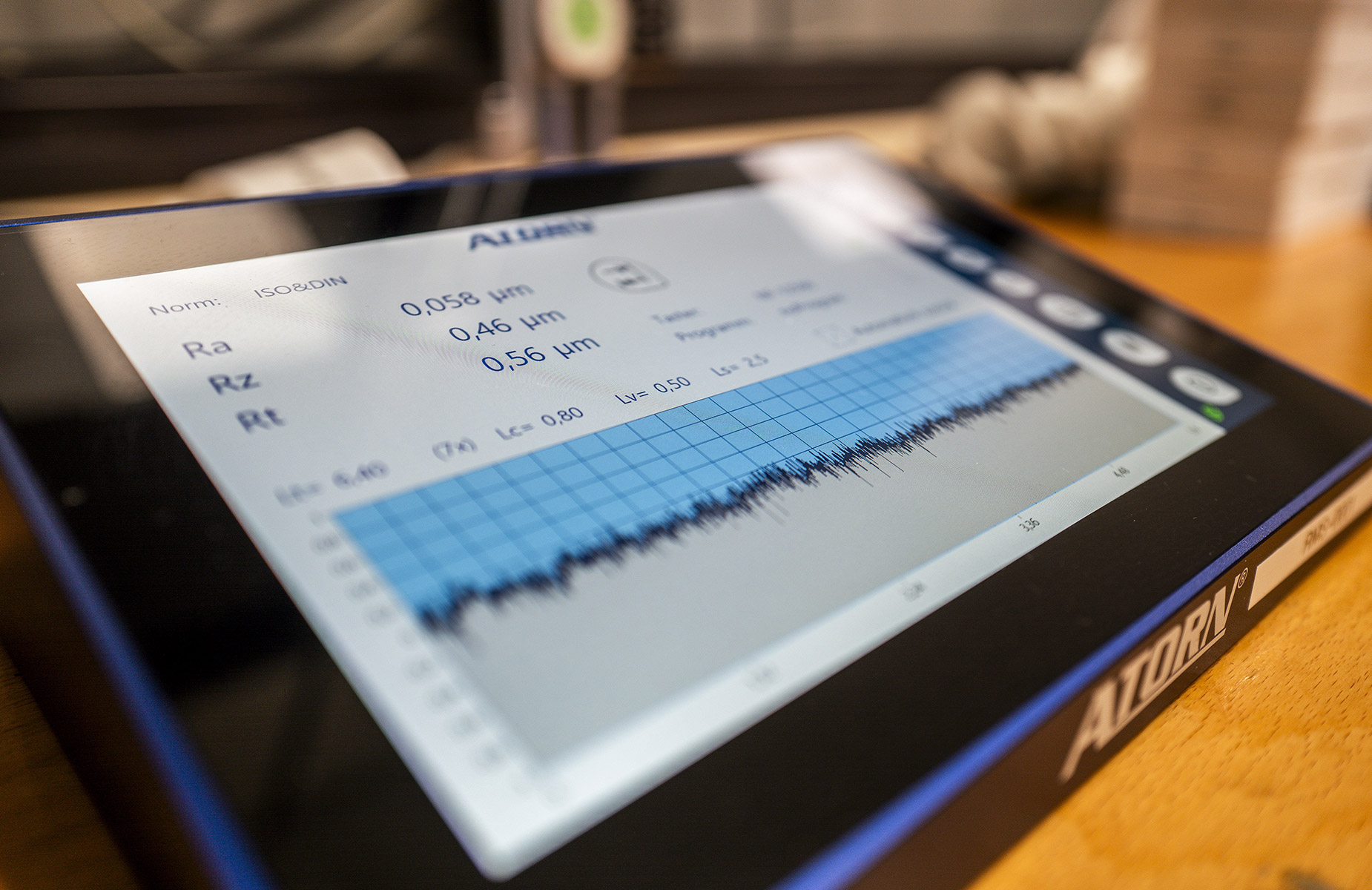

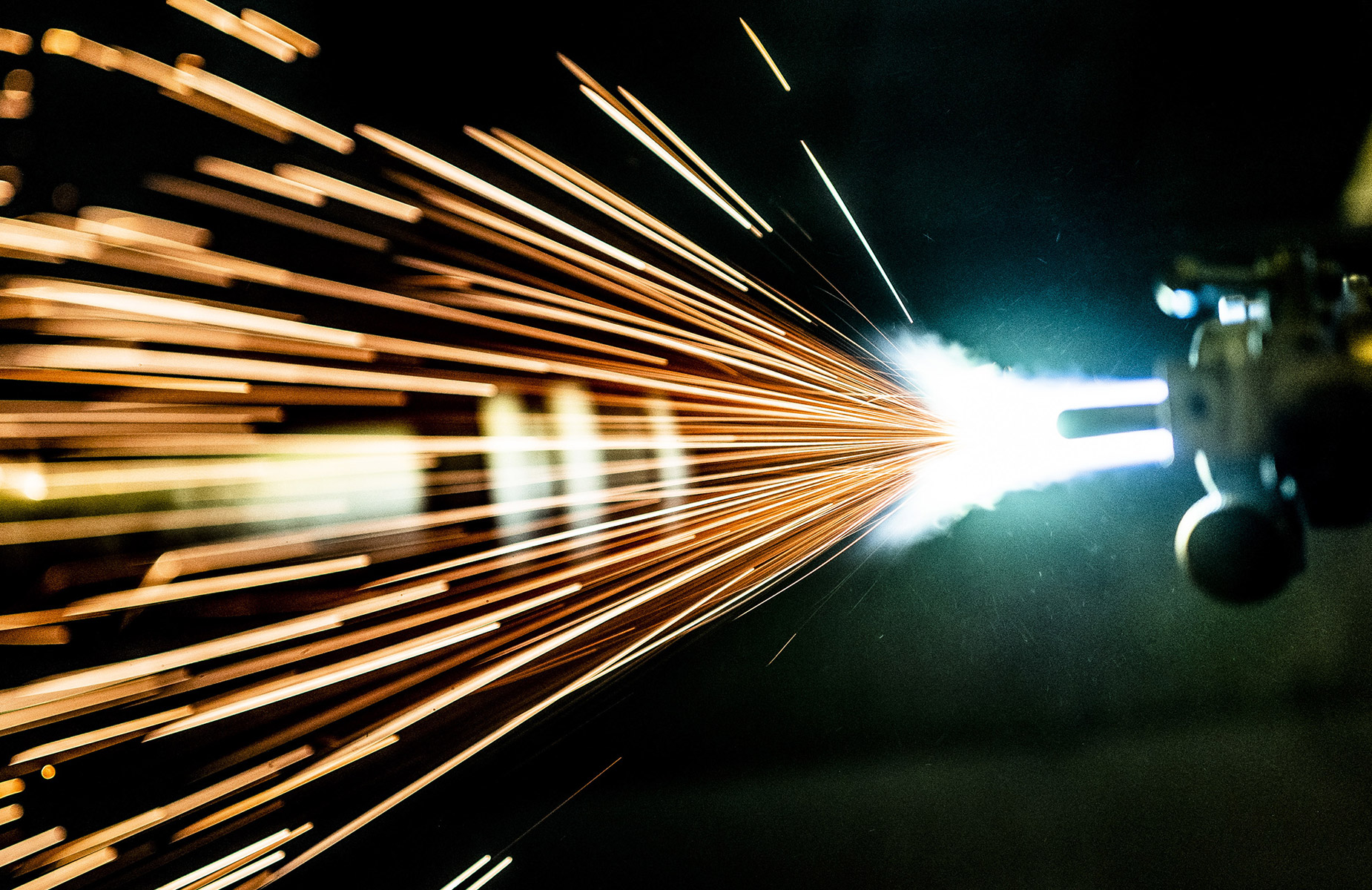

Surface Finishing: Grinding and polishing for ultra-smooth, low-friction surfaces

-

Ceramic Processing: Precision forming of alumina and zirconia components

-

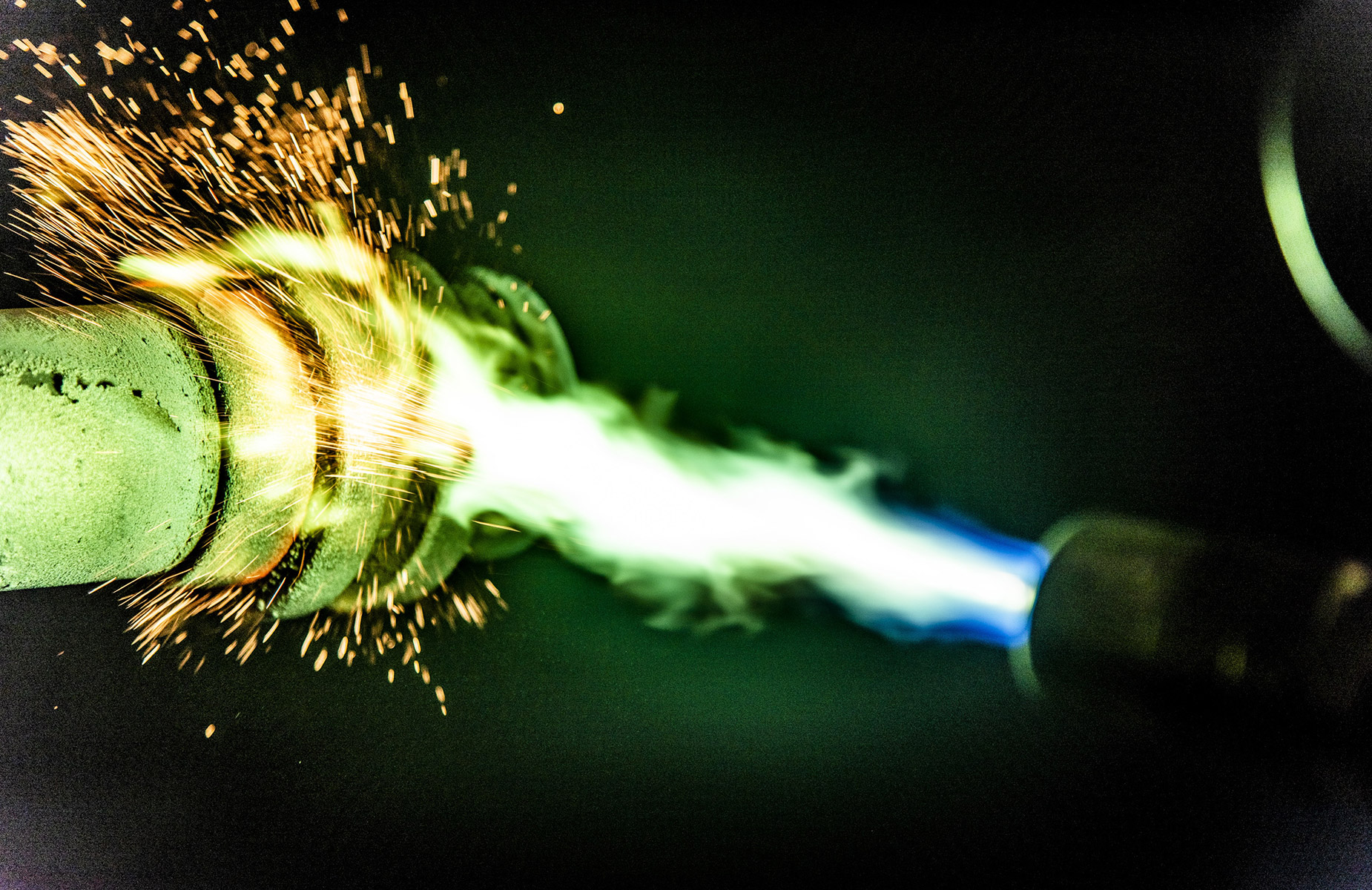

Special Coatings: Steel–ceramic composites, hard chrome, tungsten carbide

-

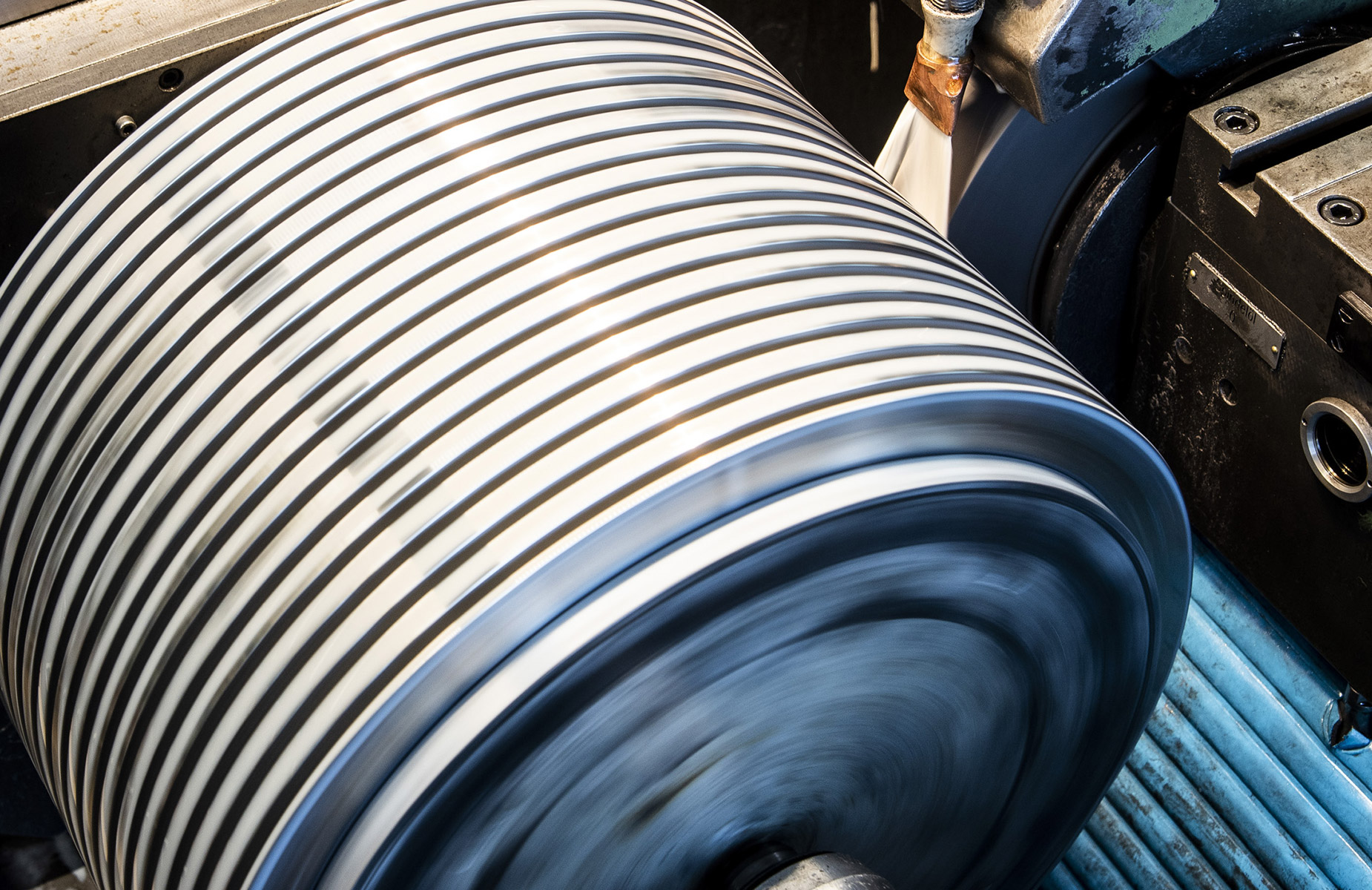

Dynamic Balancing: For high-speed rotating parts like pulleys and capstans

-

Custom Assembly: Integrated builds with tight tolerances and functional alignment

Custom Tool Manufacturing

Single & multi-wire drawing lines

Rod breakdown and fine wire lines

Resistance annealing systems

Bunching, stranding, and coiling units

Make Your Best Tools Last Twice as Long

Service & Tool Refurbishing

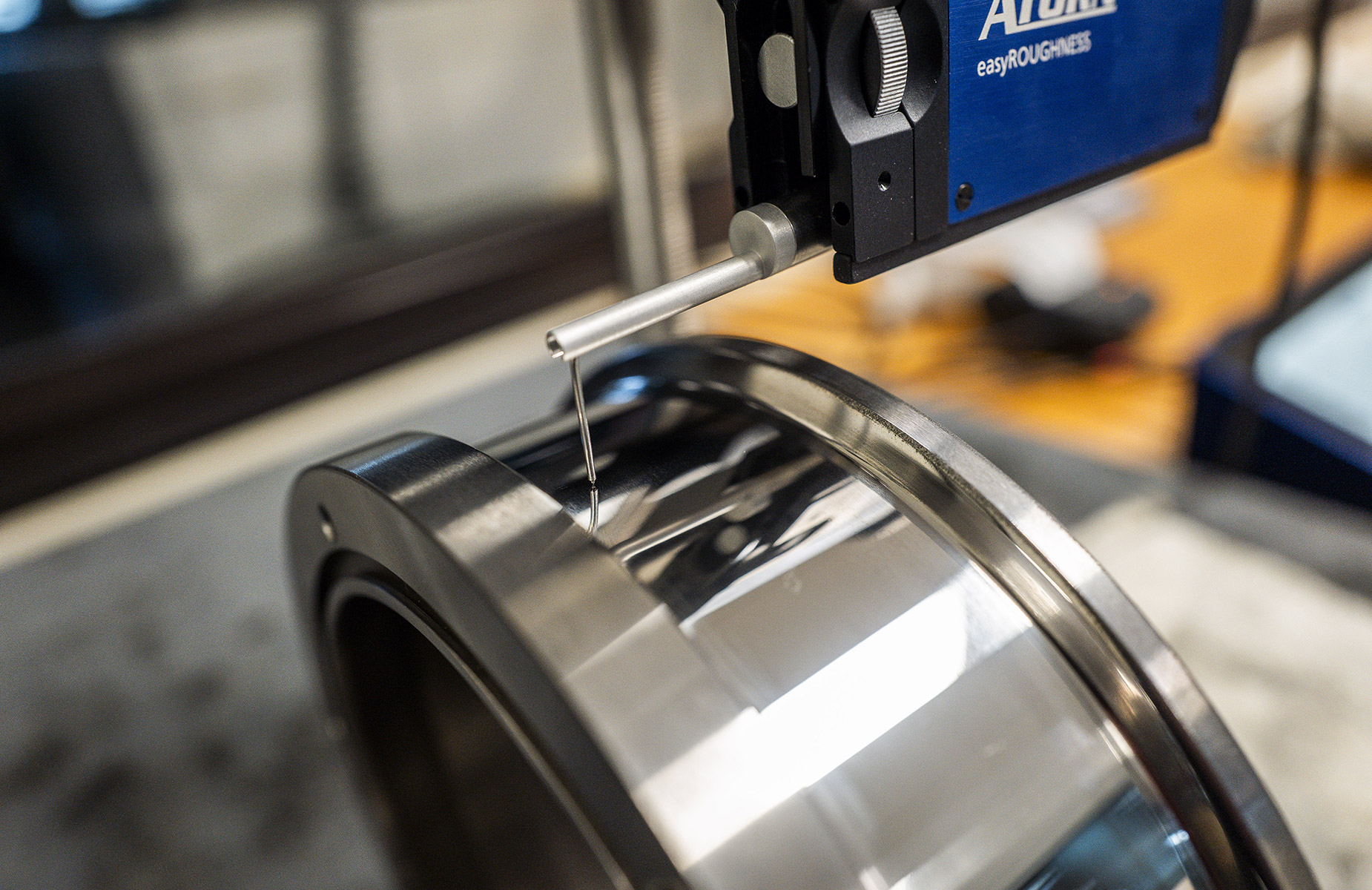

Collect & Inspect

we analyse wear patterns under 3D microscopy.

Precision Rebuild

re-grind, coat, balance and certify.

Return Ready-to-Run

performance equal to new, at up to 60 % cost savings.

Production Capacity

Product

Capacity (per year)

Capstans

2,000 – 2,500 pcs

Contact Tubes

1,500 – 3,000 pcs

Guide Pulleys

2,000 – 3,000 pcs

Ready to optimise your next wire run?

Take the first step toward longer-lasting parts and fewer line stops.